Gaui 500x Foldable Quad Flyer

Friday 13th January 2012

Specifications

Manufacturer: Gaui

Model: 500x Quad Flyer

Materials: Aluminium, Glass Fibre, ABS Plastic

Size:

Weight (Frame Only):

Price for Frame: £105.49 at Fast-Lad Performance

Equipment Installed / Setup

Motors: 750Kv

ESC's: Turnigy Plush 18amp v3.1

Controller: OpenPilot CopterControl

Firmware: 19/08/11 - 419

Blades: 9x4.7 & 10x4.7 SF E-Prop

Batteries: Turnigy Nano-Tech 3 Cell 2200mah 25-50C

Reciever: Spektrum AR6210 DSMX

AUW:

Flight Times: 7-8 Minutes

OK So finally decided to get a quad but I must admit it wasn't my first choice, I always thought Quads looked boring, everyone was building them and they didn't fly great in fast forward flight but then I asked the question "What did I Really Want Out of a Multi-Rotor Plateform?" At the mement I find myself taking more pictures than videos so because of that it had to Powerful to carry a compact camera, stable to get nice clear pictures and light weight so I could get time to get that perfect picture without running out of batteries - Quad? Yes!

Adobe Acrobat document [10.2 MB]

I searched around the internet forums, shops and thought about building one out of wood/glass fibre like the Tricopters but after a month of searching I set my heart on the Gaui 500X Quad flyer for various reasons - It had good reviews, was foldable, looked the part and christmas way looming.

Fix the otherside of the outer arm holders with four M3 x 8mm screws complete with one M3 gold Washer. Again make sure this is tight enough to still hold but again allow a sliding movement. The Washer is there to act as a locking mechanism to lock either the arms folded or open.

Take both sides of the motor mount & insert the spring type landing gear in the recessed slot. Using the M2 x 5mm screw & nut tighten the two halfs to hold the landing gear in place, next take the three M3 x 12mm self tap screws & insert these into the remaining holes, tighten to hold together remembering these will have to be loosened again to fit the arms.

Slide the motors in through the top and line up the four holes with the base plate, tighten using four M3 x 5mm screws while remembering to add thread lock blue. If you don't have screws available there is a "Motor Screw" Kit which fit perfectly. Do the above for the other three motors.

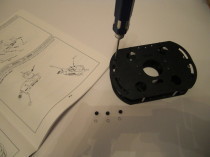

Next up its time to modify the ESC as the original cables are a little short so the picture to the right shows the process. First cut open the heat shrink and desolder the three motor end cables so longer ones can be soldered on. Now reheat shrink to make sure nothing shorts out with any moisture in the air.

The Plush 18amp speed controllers are a little big to fit inside the arms so I needed to drill two 8mm holes on the side of the arms to allow both sets of wires to be fed through. Once these were drilled I tidied up the holes with a file to save any damage happening from sharp edges & also used "hot Clue" to hold the cables in place.

One thing I thought was a fantastic idea and one I hadn't seen before until I build this bird was a 4 in 1 connector so you can connect all the positives together and all the negitives to the battery using 3.5mm bullit connecters with no hassle. Highly recommended - Part Number 222175 but can also be found at HobbyKing.

After soldering all the bullit connectors and fixing the cables in place it was time to add my chosen flight controller which in this case is the Open Pilot Copter Control which I was having lots of issues with on the Tricopter so basically if it didn't work here it was time to sell. The good news was that is did in fact work a lot better than expected, still a few twitches from time to time more so in the wind but over all I am happy.